- Units for heavy duty units with independent twin ram grapple

- Material wider than unit width can be clamped

- Toeplate options with bolt

- Quickhitch mount to facilitate rapid changeover

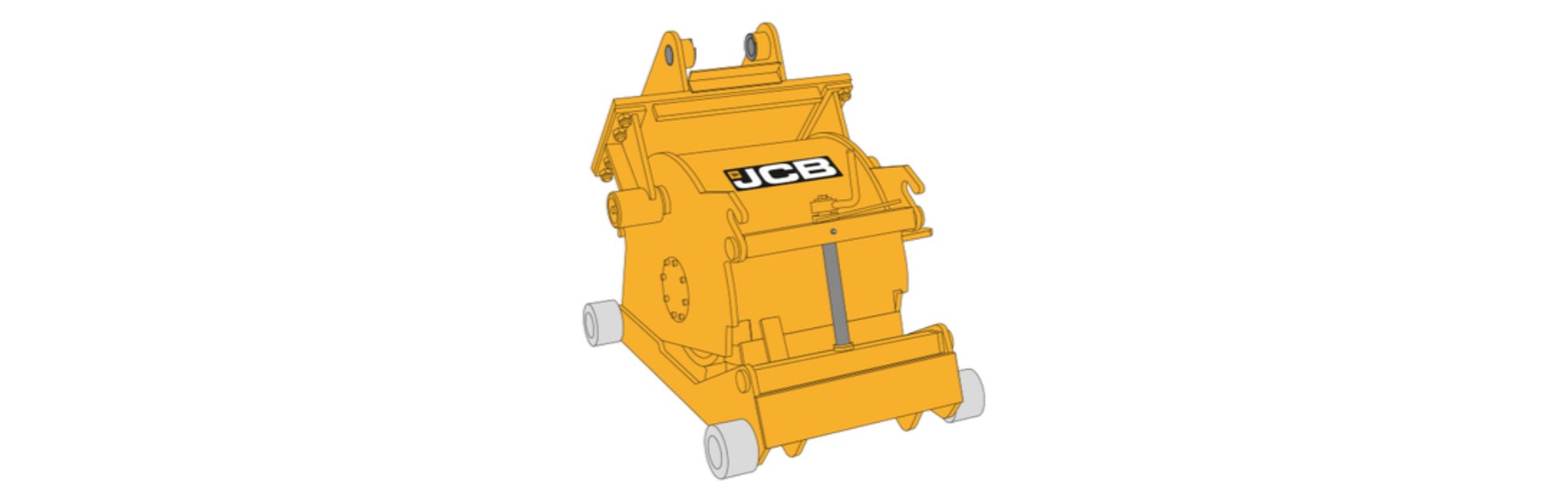

SC150 / SC150HD

- Q/Hitch configuration for maximum changeover time, improved productivity and operator safety

- Sweeps, collects and dumps to maintain site cleaning and better working environment

- Direct drive motors for excellent torque to maintain optimum performance

- Large capacity bucket for longer sweeping cycle

- Fitted with flow control valve to protect the drive motor

Ripper Tooth

Rakes

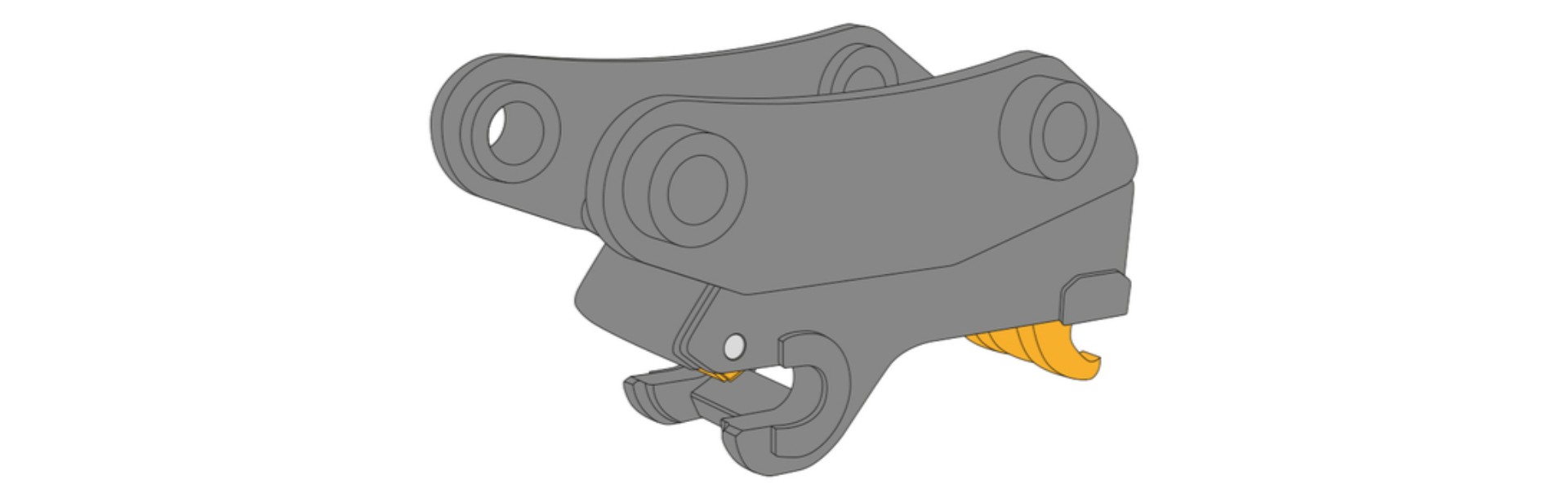

Excavator Quick Hitch Manual

- Mechanically operated quickhitch with spring load release reduces changeover time of excavator attachments

- Greater operator safety and reduced effort

Incorporated safety lock pin prevents accidental loss of the bucket or attachment - A proven durable design with hardened steel jaws optimises the customer’s investment

Excavator Quick Hitch Hyradulics

Patch Planer

- Connected to Hi-Flow Circuit to allow operator precision planning up to a depth of 115mm

- 400mm wide cutting drum ensures that only minimal amount of road is planned, ensuring cost effective reinstatement

- Easy adjustment of wheel configuration to allow operator to plane up to the kerb/grid edge

- Replacement tooth picks to allow operator to maintain high production from the unit

Patch Planer – General

- Connected to the Hi-Flow Circuit to allow operator precision planning up to a depth of 115mm

- 400mm wide cutting drum to ensure minimal amount of road is planned, ensuring cost effective reinstatement

- Easy adjustment of wheel configuration to allow operator to plane up to the kerb/grid edge

- Replacement tooth picks to allow operator to maintain high production from the unit

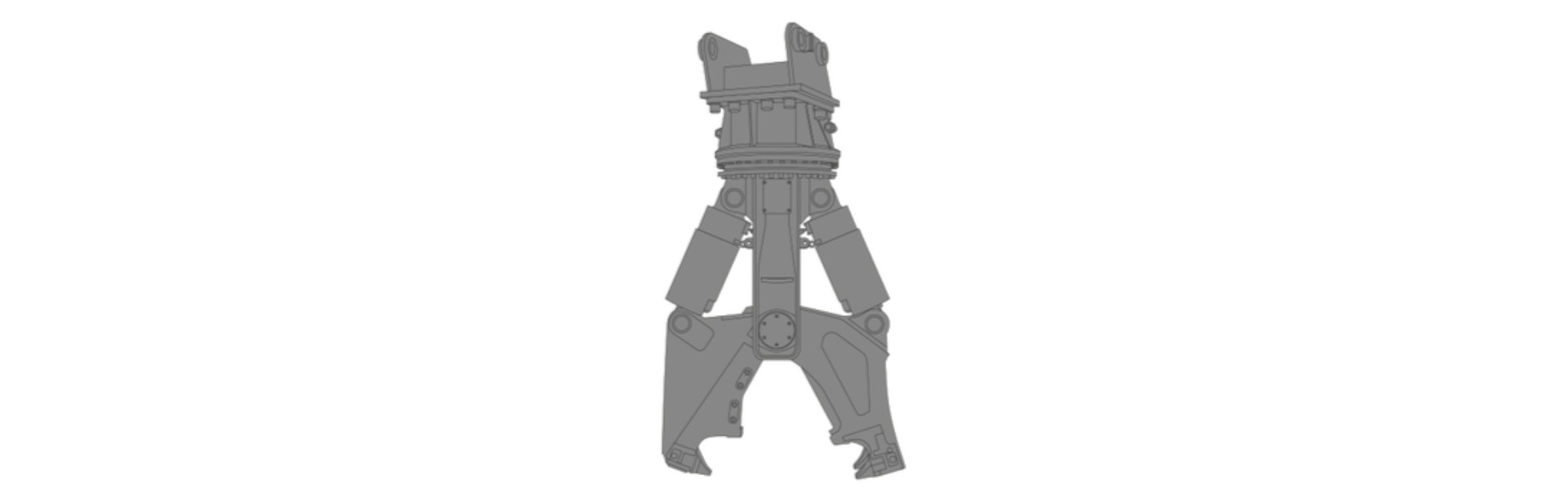

MP400

- To demolish buildings in a safe and controlled manner

- Allows the material to be easily removed, processed, seperated and recycled

- Heavy duty rotation unit offers unlimited 360º rotation

- All wear parts easily replaced on-site without workshop facilities

- Supplied ready to use with hoses and hanger bracket

- The JCB Multiprocessor MP400 has a maximum cutting force of 400T

- Maximum jaw opening of 1010mm, weighing 3423kg

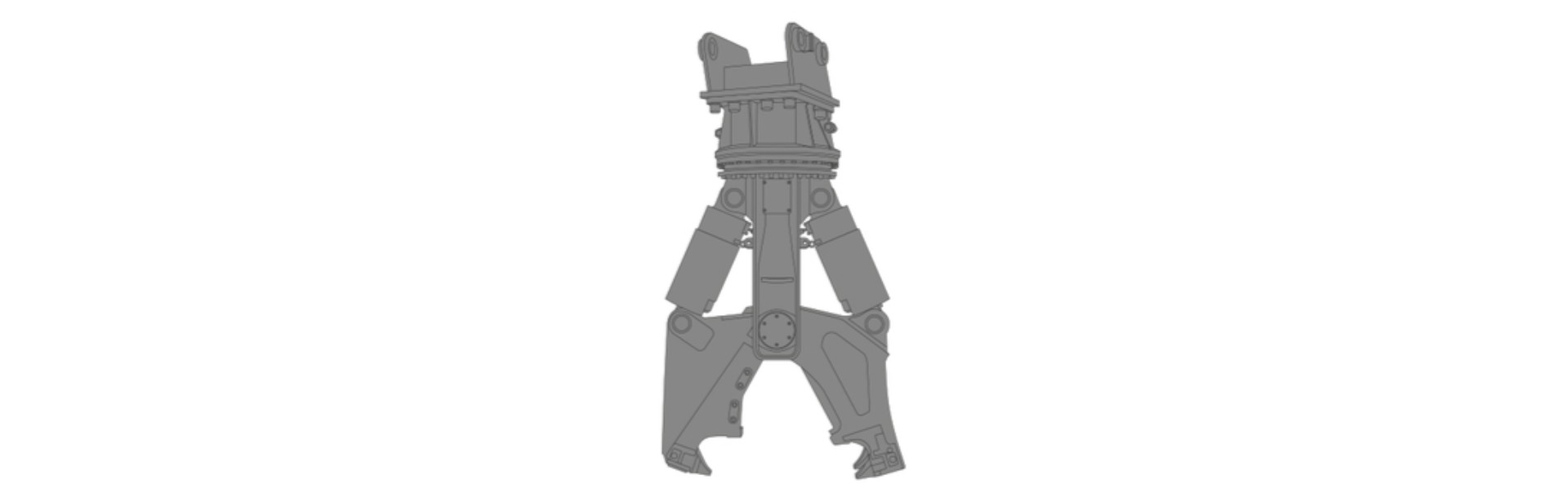

MP300

- To demolish buildings in a safe and controlled manner

- Allows material to be easily removed, processed, separated and recycled

- Heavy duty rotation unit offers unlimited 360º rotation

- All wear parts easily replaced on-site without workshop facilities

- Supplied ready to use with hoses and hanger bracket

- Maximum cutting force of 300T

- Maximum jaw opening of 880mm, weighing 2740kg