Skip to content

- Choice of 20 l/min or 30 l/min flow rate models available

- This unit weighs 15 kg

- This unit’s vibration rate is (BS8622-5) 6 m/s2

- One of the lowest vibration levels of any equivalent breaker is provided by vibro damped handle

- Low noise (no exhaust port) and elimination of freezing problems are caused by sealed hydraulic system

- For maximum strength and durability, there is a robust cast steel construction

- High reliability and long service life – only two moving parts and constant lubrication by hydraulic oil

- Single or twin ram option is available

- To aid material retention, this unit is fitted with top grab

- Fully protected hydraulics available

- For rapid changeover times, there is a Quickhitch mount

- This dipper mounted unit is designed for the safe and simple way of manipulating kerbstones up to 70kgs. with a maximum grab opening of 170mm

- Manual rotation is available in this unit

- For the operators additional safety, this unit is equipped with hose burst check valve

- Without causing any damage to the kerbstone, the wearparts give good gripping properties

- This unit is designed for demolition, recycling and any job requiring waste handling

- This unit is fully covered hydraulic cylinders and motors, and hose burst check valve

- To increase life and make repair easy, there is reversible bolt on cutting edges

- It is supplied ready-to-use with hoses and hanger bracket

- For pallet forks, this unit has quickhitch compatible frames

- For uneven ground and loads this unit has floating pin style fitment

- Fork pin completes this unit

- Changeover time is maximised, productivity and operator safety are improved by Q/Hitch configuration

- Adjustable fork centres enables the operator to position the forks in the safest loading point

- Effective production time increases when changeover time decreases

- The JCB frame mounted unit can drill 150mm – 915mm holes upto 1.8 mtrs depth

- Long service life, minimal maintenance and lower service costs are possible because of sealed planetary gear reduction and heavy duty gear design

- To suit most applications the operator might encounter, a wide range of flights are available

- A standard 50mm hexagon drive with a shear pin is fitted in this unit to maximise the user’s safety

- To maintain a high production rate and to extend the life of the flight in operation, a range of replacement wear parts are available

- JCB designed dipper mounted unit can drill 160mm – 460mm holes upto 2.2 mtrs depth.

- To suit most applications the operator might encounter, a wide range of flights are available

- A standard 50mm hexagon drive with a shear pin is fitted in this unit to maximise the user’s safety

- To maintain a high production rate and to extend the life of the flight in operation, a range of replacement wear parts are available

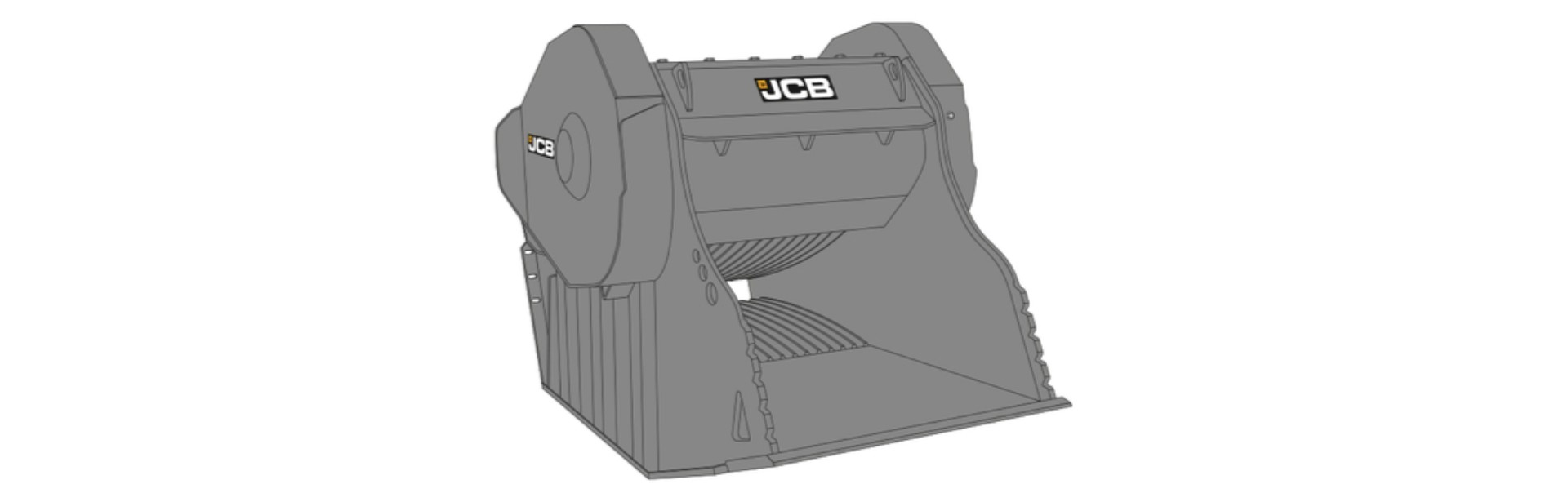

- This unit is specially designed for on-site crushing of demolition material (e.g. reinforced concrete, rubble, hardcore) between 100mm and 20mm

- It can easily crush material with reinforcing bar to recover steel for scrap

- It is supplied ready-to-use with hoses and hanger bracket

- For sustained crushing action, patented flywheel uses machine’s hydraulic power

- This 3950kg unit has a maximum output of 40m3/h with its opening width and height of 900mm x 450mm