Skip to content

This unit is designed to provide optimum performance on the JCB machine without invalidating machine warranty

This unit is not only capable of reducing brick, concrete rubble and rock to hardcore size but also provides a cost effective alternative to a mobile crushing plant

Used in small quarries and construction/demolition sites, this unit further enhances the earning potential of the carrier machine

This unit is designed specifically for on-site crushing of demolition material (e.g. reinforced concrete, rubble, hardcore) between 100mm and 20mm

It can easily crush material with reinforcing bar to recover steel for scrap

It is supplied ready-to-use with hoses and hanger bracket

For sustained crushing action, patented flywheel uses machine’s hydraulic power

This 1725kg unit has a maximum output of 19m3/h with its opening width and height of 600mm x 450mm

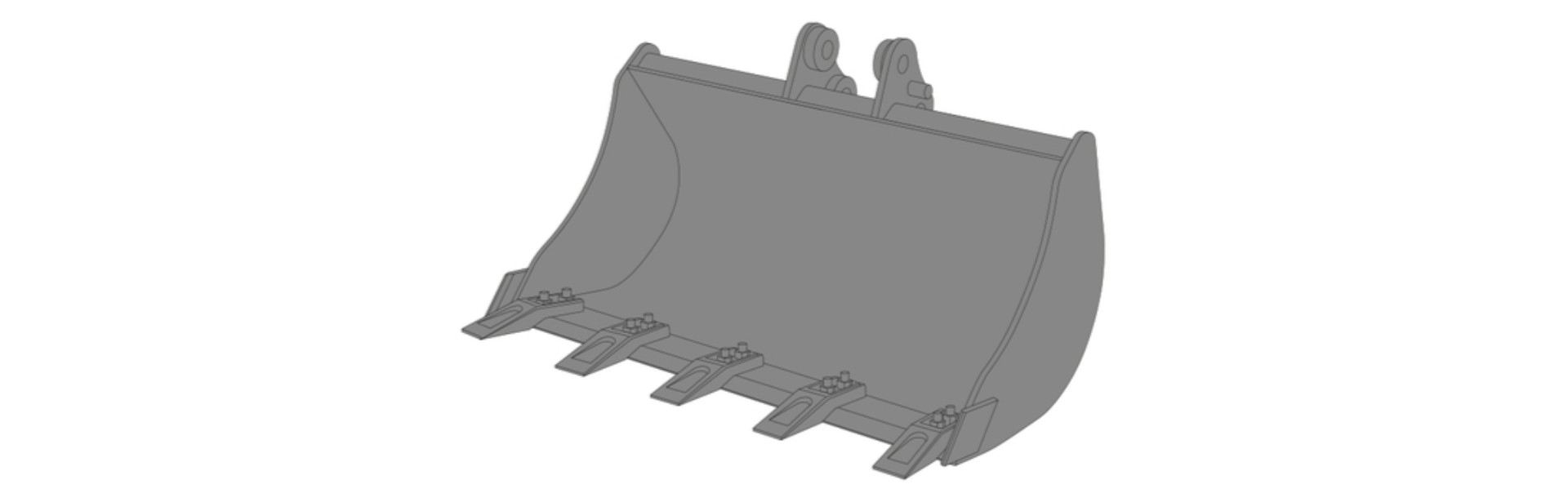

This bucket is specially designed and manufactured to match the machine capability

Without the need to keep re-positioning the machine, this bucket allows greater operator flexibility.

This bucket has a selection of profiles that enables the operator shallow or steep sided ditch forming.

Structural integrity and durability is increased by the double box section cross beam.

To help increase service life, this bucket is fitted with standard wear parts.

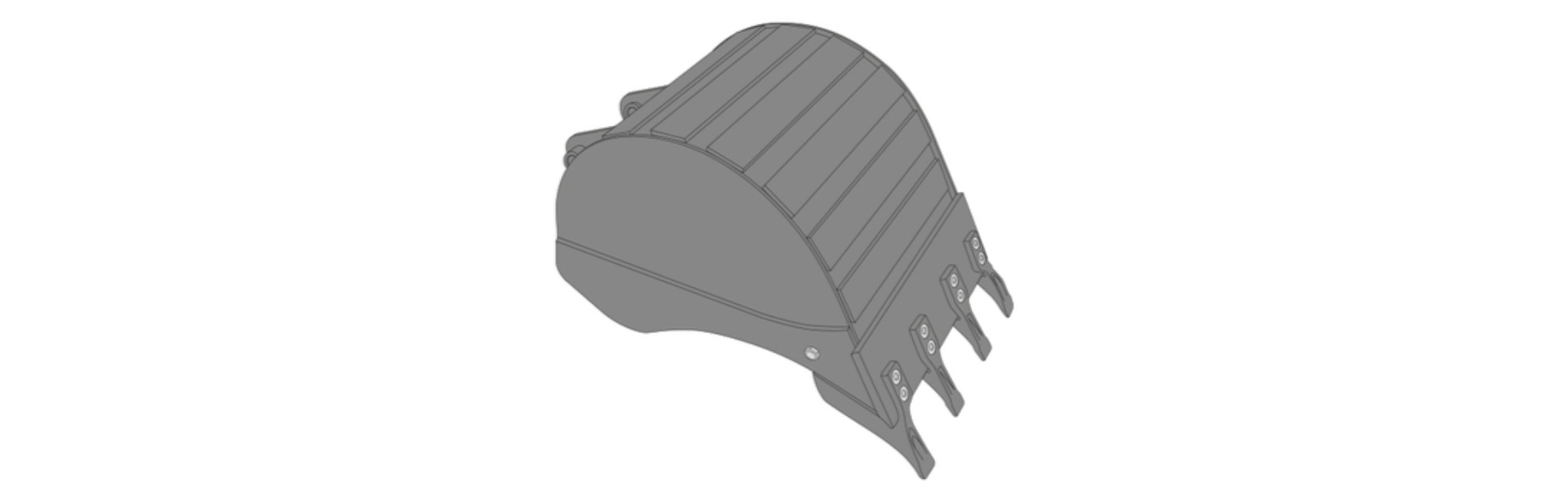

This bucket is designed for specific municipal applications.

This bucket is manufactured and designed specially to match the machine capability.

On wear-parts, a range of replacement bolt is available. It will prolong durability and will help in maintaining maximum production.

This range offers the operator a large selection of widths to suit the requirement and to minimise trench backfill

The range has been designed and manufactured to match the machine capability

A range of replacement bolt on wearparts are available that will prolong durability and maintain maximum production.

Offers the operator a large selection of widths to suit the requirements and to minimise trench backfill

Cat style 394 wear parts and side cutters with tough robust design help maintain high production and prolong service life.

Complete with bucket pins to facilitate use of the quickhitch

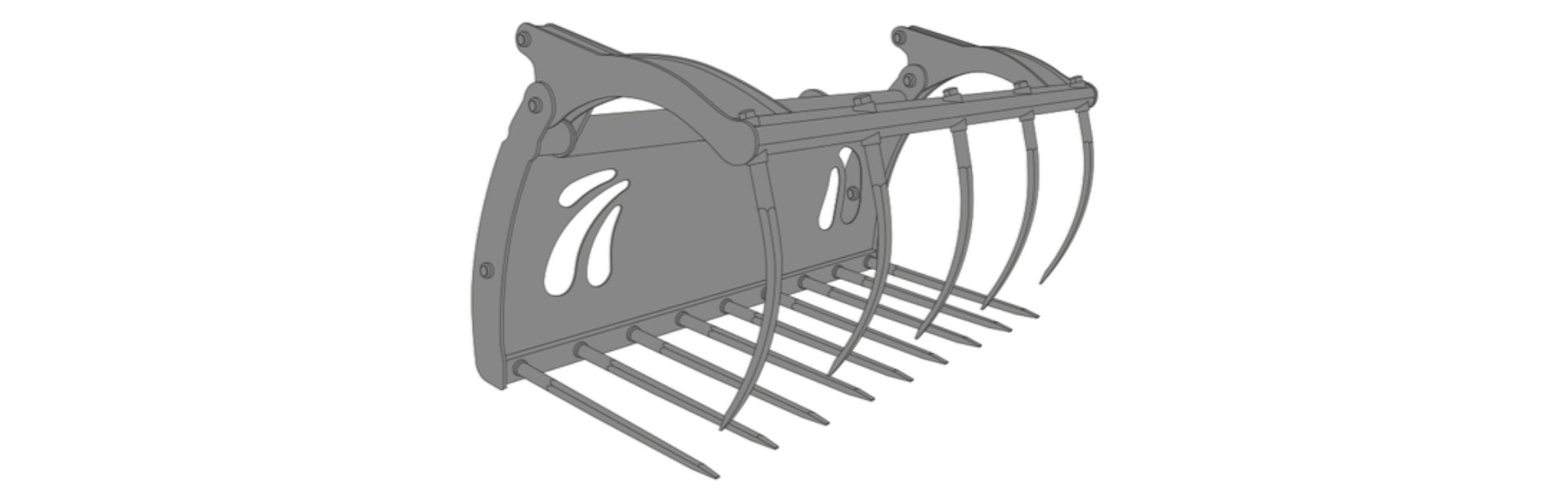

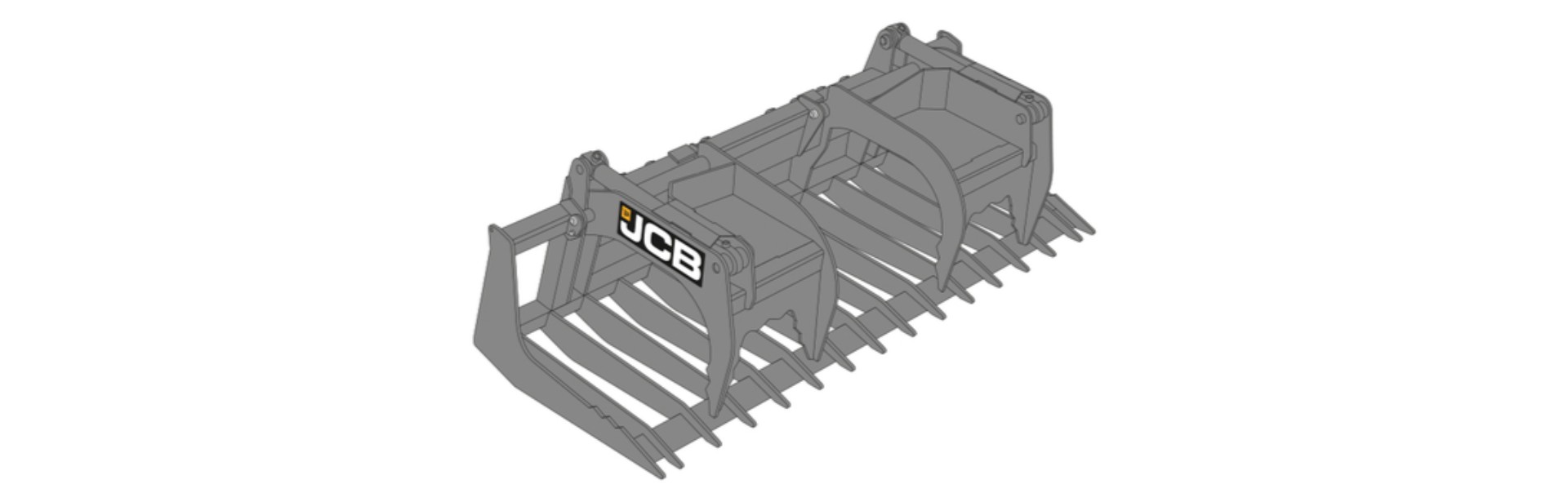

To suit all applications, there is a Choice of KV or Hardox tines

For optimum penetration and tearout, there are powerful twin top rams

For operating close to walls, there is a wide opening jaw with curved top tines

Changeover time is maximised, productivity and operator safety are improved by Q/Hitch configuration

The material securely held in place by dual independent grapples

For greater operator safety, this unit is fitted with check valves

To further extend service life, replacement wear parts are available

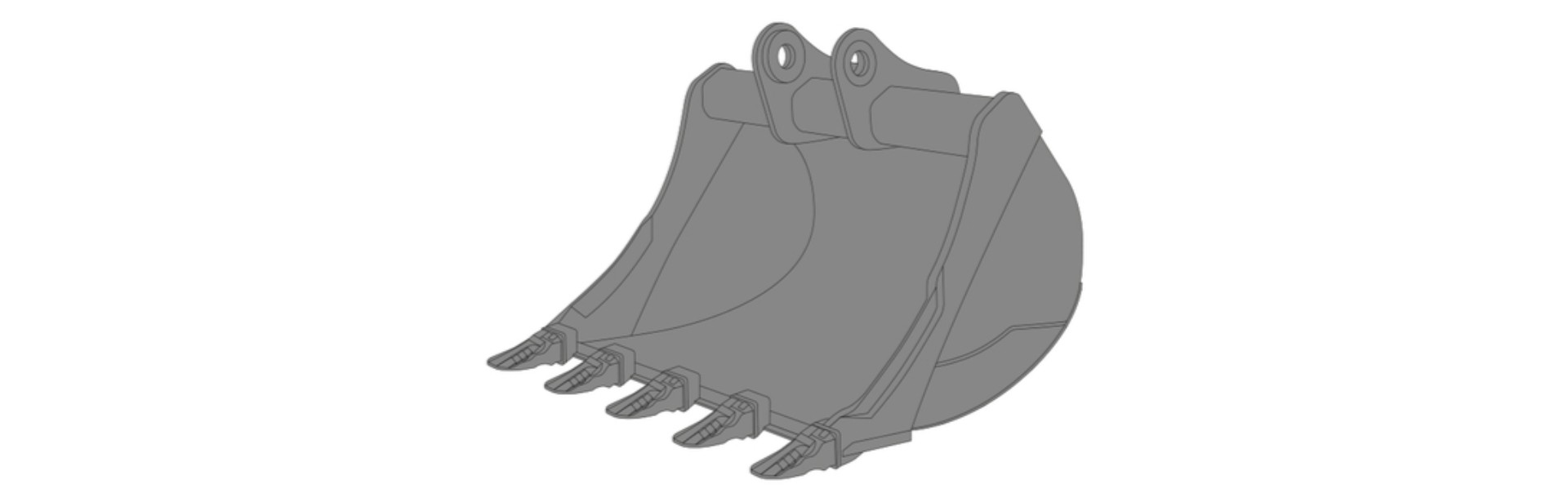

Designed and manufactured to match the machine capability

Can be used as a standard digging bucket or a powerful hydraulic jaw.

The design with its additional wear strips offers increased strength and wear resistance